In this article you will find

instructions and tips about setting of the floating vibrato unit (also

inappropriately called tremolo) of an electric guitar,

with special regard to models often used on super-strat style instruments. This is part of the general setup of the guitar,

that involves topics covered on the Soundsation blog as intonation, pickup and action adjustments.

Before continuing you should

have:

All that verified, we can talk

about how to self-adjust a vibrato bridge with two studs and springs.

Please take note that the setting of a Fender

vintage style six screw vibrato is debated in the Soundsation blog article “The setup of your guitar (PT. 7) –Setting a vintage style vibrato”, largely valid for floating bridges with two studs without a locking nut. Examples are the

G&L Dual Fulcrum Vibrato that Leo Fender introduced in the '80s, the

Fender 2-Point Synchronized Tremolo featured on 1986 Dan Smith's and

George Blanda's American Standard Stratocaster, the Wilkinson VS100N (left photo below),

the Music Man Standard, the Gotoh NS510T-FE1 (right photo below) and similar ones, of which we are going to talk here.

How are floating bridges made?

Talking about stud mount bridges with just two

studs/screws instead of traditional six screws, the most popular are those in

the Fender American Standard style and various types of Wilkinsons, the latter

designed and introduced in 1986 by Trev Wilkinson, musician, hardware

and pickup inventor, founder of the English brand Fret-King. He also designed

the Roller Nut, used on some strats since 1987 and replaced by the

Fender LSR in the early '90s.

Wilkinson parts are currently made by Japanese Gotoh

and Korean Un Sung.

Almost all guitar and hardware manufacturers

have these kinds of floating bridges in their list, mostly matched at the

headstock by locking machine heads of brands such as Gotoh (left photo below), Schaller and Sperzel (right photo below). These tuners clamp strings in the shaft

holes and prevent tuning loss when the vibrato arm is heavily handled.

Materials floating bridges are made of are essential

for their mechanic and sound quality. Certainly steel has to be preferred at

least for saddles, because it provides the highest vibration transmission

speed and a good sustain.

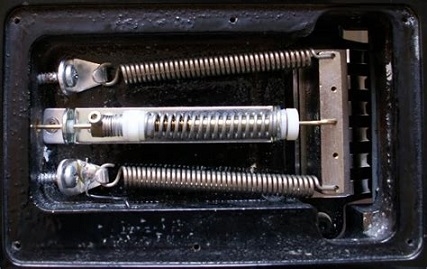

Tremolo blocks (or sustain blocks) are often made of aluminium, brass, titanium,

zinc alloys (especially Zamac: Zinc Aluminium Magnesium) and also

pressed metal powder in cheaper models, as the '80s Fender Am Std, poor

in terms of sound and duration. Studs and plate knife edges are very

important for bridge duration and operation smoothness. G&L

fifty year old tremolo, by example, features hardened steel for the bridge

frame, the sustain block and the studs, whereas the threaded

anchors dipped into the guitar body are made of brass. Saddles are made of stainless

steel. Considering the hardness of this material compared to hardened

steel, string to saddle contact point must be very well machined in order to

avoid friction and breakage. Knife edges to studs joints are circular

and wraparound, a useful feature during string changing, as we'll see.

Wilkinson VS100N plate is made of hardened steel;

studs, saddles and arm are made of stainless steel; the sustain block of zinc

alloy. It's a great product, and it can also replace the American Standard

tremolo with no modification. However, it is always good to turn to a luthier!

Floating bridge advantages

- General lightness

and two stud swinging give floating bridges greater fluidity and ease

of use if compared to vintage style bridges.

- These bridges with

matching locking tuners and well cut self-lubricating nuts (or roller

nuts) allow wide intonation excursions with no tuning loss, both in up and

down ways.

- In the finest models,

saddle clamping to the bridge plate, together with the above described

points, provide tuning and intonation retention for a long time,

virtually making setup controls necessary only at string change.

Floating bridge downsides

- Instrument overall

sound is somewhat different from the one of a typical vintage style strat, with an apparently minor contribution of body wood in

favour of bridge metal. By example, Wilkinson bridges can emphasize a

metallic resonance around 2000 Hz (spike). If this not appreciated, the

problem can be solved by the adoption of saddles made of alternative materials

like GraphTechs.

- According to some

experts, other metal contributions to sound come from locking tuners, that are

heavier than vintage style ones, and from eventual metal nuts as roller ones.

- The presence of only

two balance points and a thinner sustain block (in order to prevent beating on

the body during up/down bridge movements) can induce a strange sound

fluctuation called warbling when playing on the higher portion of

the fretboard, after the 12th or 14th fret. If this event

occurs, it is solved on prestige guitars by the adoption of stabilizers

like the Hipshot Tremsetter and similar others, a sort of dampers that

in addition ensure a decidedly lower intonation drop of open strings during

bending and, generally, an even smoother operation of the vibrato.

- You have to replace

strings one at a time. Infact, due to

sudden tension loss, the bridge looses its grip on the studs and collapse onto

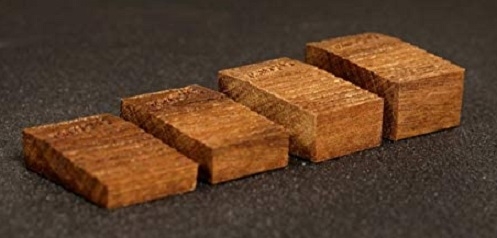

the guitar top, while springs disengage the claw. When you need to clean or

polish the fretboard, and therefore to release all the strings, it's good to put a wood, plastic or hard rubber wedge under the

rear side of the bridge, thus avoiding the circumstance. I use a purpose-built

wood block (photo below) or a pen ink eraser, but everyone can find his own

solution. Somebody prefers a fitting Post-it pad. The important thing is

not risking to damage the top paint.

Floating bridge setup

What has been written about the six screw vintage style bridge setup is also effective for floating bridges with two studs without a locking

nut, at least for the spring tension adjustment. The main difference here is

that the bridge should be parallel to the guitar top, especially

if it lies in an excavation; otherwise, you can set it flush with the

body top or angled according to your taste and need, as it happens for the

Fender Am Std.

Then proceed to tuning and spring tension in following

alternate steps until the desired result is reached.

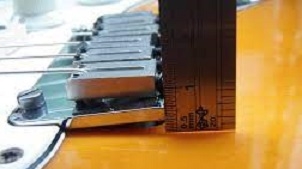

- Height (action)

Setting a floating bridge height is easy: you just

have to act on stud Phillips or slotted or Allen screws. It is important

to set the bridge plate at the height recommended by manufacturer or your

trusted luthier. Using the right number of springs (2-3), I suggest the

bridge to stay as low as possible on the guitar top as long as a

friendly use is got and the action is optimal. Like I said, some guitars

feature a recessed top routing where the bridge stays, thus keeping it

as low as possible and allowing a very comfortable action.

Once you have lowered the bridge as much as possible,

you can complete the work acting on the screw pair of every saddle.

On some floating bridges, as the Wilkinson VS100, you

have to loosen an Allen screw that secures the saddle position in order

to ensure stillness and maximum sound transmission: this has to be done before

any height or intonation adjustment.

- Radius

Using the same screw pair you have used for the saddle

height setting, try to follow the fretboard radius as you would do on a

common strat (in this regard, read our blog article).

- Intonation

Intonation procedure is the same as for vintage bridges in the case of Fender 2-Point

Synchronized (Am Std) style tremolos, that are equipped with Phillips screws

inserted from the back (you can read our blog article).

- Arm

At this point you still have to adjust the arm

height in its position and your preferred rotation friction. Modern

bridges provide setting by means of a spacing screw under the arm hole and a little

Allen screw radial to the plug point. This applies when the arm and the

hole are not threaded.

Some arms have removable nylon rings to set the

friction plug-in.

If you have any doubt, especially if the nut is height

adjustable with screws or shims, turn to your trusted luthier.

Floating is OK, but there's more

than this

Construction accuracy, quality materials, locking

machine heads and a good setup provide a flowing, easy and reliable

use of the arm on floating bridge equipped instruments, without tuning loss

not even if you are exceeding in swing – within certain limits. There was a

time though this was not the situation, and it was necessary to turn to the

only possible choice: the Floyd Rose bridge, still unrivalled for a

“wild” use of the vibrato. This subject is dealt with on the fantastic

Soundsation blog, along with the Kahler vibrato, the other great

competitor in the '80s/'90s!

Fabrizio Dadò